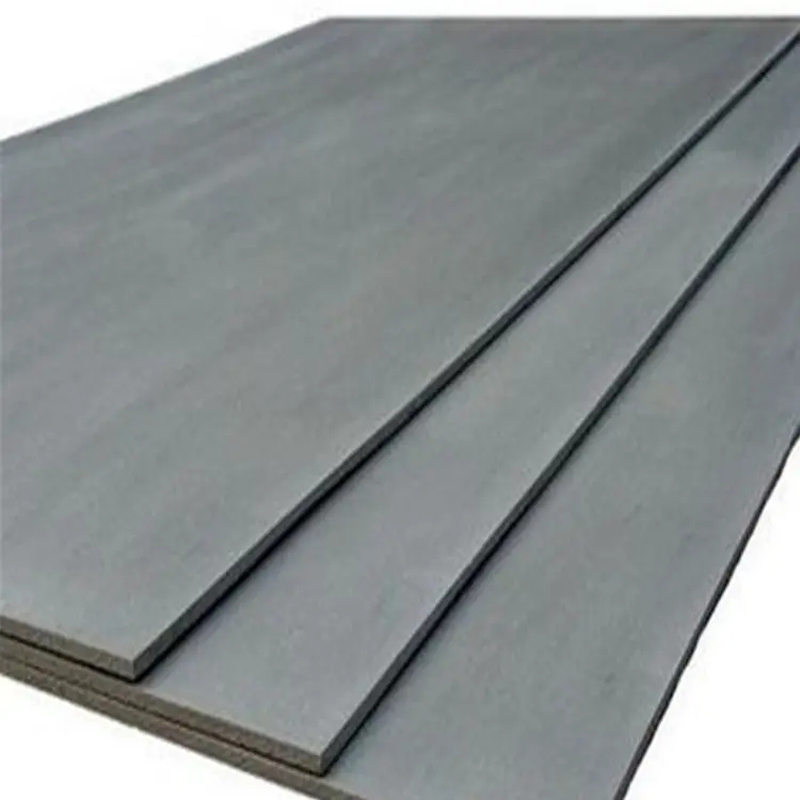

SA588 SA387 Alloy Steel Plate

Saamaynta walxaha alloy ee hab-socodka sifooyinka birta

1. Saamaynta walxaha alloy ee waxqabadka shubista birta

Heerkulka hoose ee xariiqyada wejiga adag iyo dareeraha iyo cidhiidhiga aagga heerkulka crystallization waa, si ka wanaagsan waxqabadka shubista.Saamaynta canaasiirta daawaha ee waxqabadka shubista waxay ku xidhan tahay inta badan saamaynta ay ku leeyihiin jaantuska wajiga Fe-Fe3C.Intaa waxaa dheer, walxo badan, sida Cr, Mo, V, Ti, Al, waxay sameeyaan barta dhalaalka sare ee carbide ama oxide particles ee birta, kuwaas oo kordhiya viscosity ee birta, yareeyaan dareeraha, oo sii xumaanaya waxqabadka shubista.

2. Saamaynta walxaha alloy ee mashiinka caagga ah ee birta

Habaynta caagagu waxay u qaybsantaa habaynta kulaylka iyo habaynta qabowga.Walxaha daawaha galay xal adag, ama samaynta carbide (sida Cr, Mo, W, iwm), hagaajinaysaa caabbinta qallafsan kulaylka ee birta iyo hoos u dhac weyn ee thermoplasticity oo ay fududahay in la been abuurto iyo dildilaaca.Waxqabadka habka kuleylka ee birta daawaha guud ayaa aad uga xun kan birta kaarboonka.

3. Saamaynta walxaha daawaha ee alaabta alxanka ee birta

Walxaha daawaha ah dhamaantood waxay hagaajiyaan quenability ee birta, kor u samaynta unug jajaban (martensite), oo ka dhigi waxqabadka alxanka mid xun.Si kastaba ha noqotee, birta waxay ka kooban tahay tiro yar oo Ti iyo V ah, taas oo hagaajin karta waxqabadka alxanka ee birta.

4. Saamaynta walxaha alloy ee birta goynta waxqabadka goynta waxqabadka waxay si dhow ula xiriirtaa qallafsanaanta birta, birta waxay ku habboon tahay in la gooyo qallafsanaanta kala duwanaanta 170 HB ~ 230 HB.Waxqabadka goynta ee birta daawaha guud waa ka xun yahay birta kaarboonka.Si kastaba ha noqotee, ku-darka ku habboon ee S, P, Pb iyo walxaha kale waxay si weyn u wanaajin karaan waxqabadka goynta birta.

5. Saamaynta walxaha alloy ee waxqabadka habka daaweynta kulaylka ee birta

Waxqabadka habka daaweynta kuleylka ayaa ka tarjumaysa dhibka daaweynta kulaylka birta iyo u janjeera daaweynta kulaylka.Waxaa inta badan ka mid ah xejin, kuleyl xad dhaaf ah, xamaasad xamaasad leh iyo decarbonization oksaydhiyaha.Birta daawaha ah waxay leedahay quenability sare, iyo habka qaboojinta yara gaabis ah ayaa loo isticmaali karaa marka la demiyo, taas oo yareyn karta u janjeera iyo dildilaaca ee workpiece ah.Ku darida manganese iyo silikoon waxay kordhin doontaa dareenka kulaylka ee birta.

Faahfaahinta Alaabta

| Heerka Birta: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Fasalka B, Fasalka C, Darajada D, A36, Fasalka 36, Fasalka 40, Fasalka 42, Fasalka 50, Fasalka 55, Fasalka 60, Fasalka 65, Fasalka 70, FasalkaJIS: SPHC, SS400, SPFC, SPHD, SPHE |

| Heerka: | DIN EN 10083, ASME SA516, ASTM A203M, ASME SA588, ASME SA387, SAE1045 JIS G4051,AISI, BS |

| Dhumucda: | 1.0-300mm |

| Ballaca: | 100-4500mm, ama sida ku xusan codsiga gaarka ah ee macaamiisha |

| Dhererka: | 1-20mitir, ama sida ku cad codsiga gaarka ah ee macmiilka |

| Xidhmada: | Dhoofinta Heerka Xidhmada |

| Codsiga: | 1.Machinery, Warshadaha maraakiibta cadaadiska. 2.Dhismaha markabka, Dhismaha Injineernimada. 3.Gaadiidka, Buundooyinka, Dhismayaasha. 4.Mechanical-ka-soo-saarka, Laamiga laamiga, iwm. |

| Mill MTC: | La keenay ka hor inta aan la rarin |

| Kormeer: | Kormeerka dhinaca saddexaad waa la aqbali karaa,SGS,BV,TUV |

| Buur Port: | Deked kasta oo Shiinaha ku taal |

| Muddada Ganacsiga: | FOB, CIF, CFR, EXW, iwm. |

| Muddada Qiimaha: | TT ama LC marka la eego |

| Adeegyadayada: | Waxaan gooyn karnaa oo laacin karnaa saxan bir ah iyadoo loo eegayo shuruudaha macaamiisha ama sawirida, baakadaha sida waafaqsan codsiga macaamiisha |

Bandhiga Warshada