-

Ku-habaynta Dhuumaha Birta Daawaha ah ee A234WP12 P1 PA22 P5

Bandhiga alaabta:

Qalabka birta birta ah ee ku rakiban waa erey guud oo ka mid ah qaybaha isku xidha, xakamaynta, beddelka, leexinta, xidhidhiyaha iyo taageerada nidaamka tuubada.Ku rakibida tuubooyinka waa qayb isku xidha tuubada tuubada.Qalabka tuubooyinka cadaadiska sarreeya waxay ku habboon yihiin qalabka uumiga cadaadiska sare, heerkulka sare ee kiimikada iyo dhuumaha cadaadiska sarreeya, warshadda korantada iyo maraakiibta tamarta nukliyeerka, qalabka kululeeyaha cadaadiska sare iyo jawi kale oo gaar ah.Qalabka tuubooyinka ayaa si weyn loogu isticmaalaa qaybo badan oo injineernimo sida dhismaha, warshadaha kiimikada, macdanta iyo tamarta.Doorkeeda muhiimka ah waa in aan la iska indha tirin.

-

Tuubo bir ah oo aan kala go 'lahayn oo loogu talagalay tuubooyinka kulaylka beddelka / kululeeyaha

Bandhiga alaabta:

Daawaynta Kulaylka-waa hab adeegsada kulaylinta iyo qaboojinta si loo beddelo sifooyinka jireed ee tuubooyinka kuleyliyaha cadaadiska sarreeya.Daawaynta kulaylku waxay wanaajin kartaa qaab-dhismeedka yar-yar ee tuubada kuleylka-cadaadiska ah, si loo gaaro shuruudaha jireed ee loo baahan yahay.Adayga, adkaanta, iyo caabbinta xidhashada ayaa ah dhowr ka mid ah sifooyinka lagu helo daaweynta kulaylka.Si aad u heshid sifooyinkan, isticmaal deminta & LT daawaynta kulaylka;sidoo kale loo yaqaan deminta & gt;, xanaaqa, annealing & lt;dhalaalay & GT;iyo adkaynta dusha sare, iwm.

-

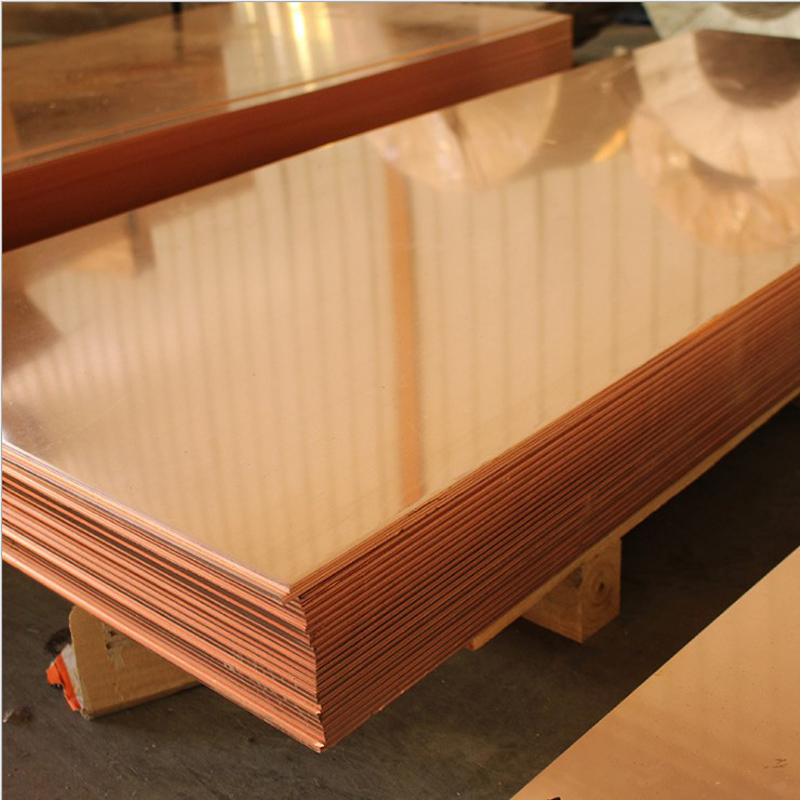

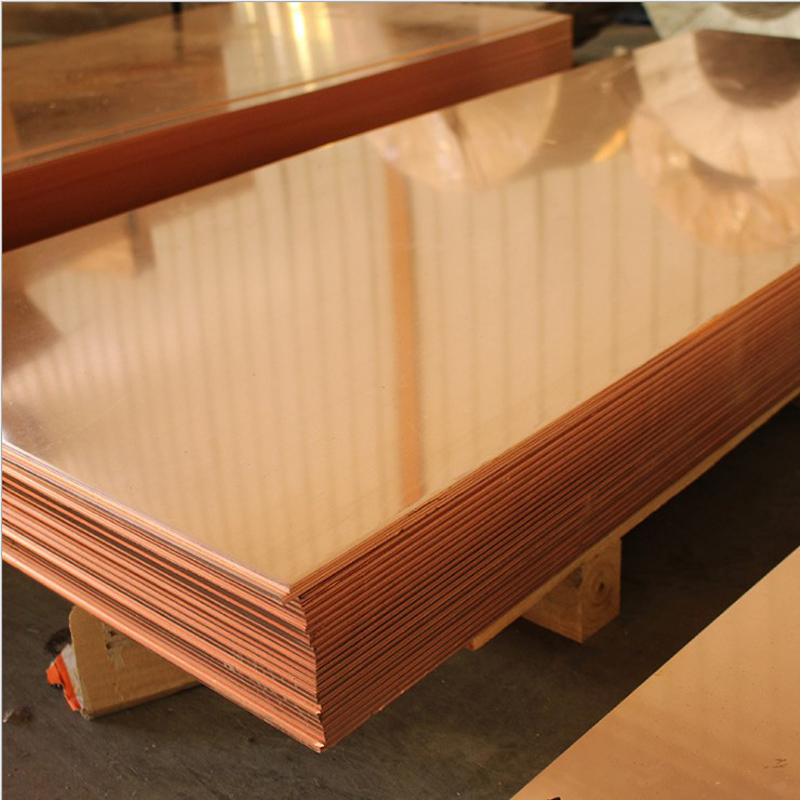

Duubabka naxaasta ah, xaashida naxaasta ah, gariiradda xaashida naxaasta ah, saxan naxaasta ah

Bandhiga alaabta:

Naxaasta saafiga ah waa naxaasta leh qadarka ugu badan ee naxaasta, sababtoo ah qaybta ugu muhiimsan waa naxaas iyo qalin, ka kooban yahay 99.5 ~ 99.95%;walxaha wasakhda ugu weyn: fosfooraska, bismuth, antimony, arsenic, iron, nikkel, lead, iron, tin, baaruud, zinc, oxygen, iwm.;loo isticmaalo in lagu sameeyo qalabka korantada, daawaha naxaasta horumarsan, daawaha naxaas ku salaysan.

Naxaasta aluminiumka waxaa loo qaybin karaa laba qaybood.Mid ka mid ah ayaa tuuraya aluminium naxaas ah si looga saaro wasakhda oo loo kordhiyo dheecaanka, daawadu kama badna 0.5%;Midda kale waa been abuur aluminium naxaas ah si ay u kordhiso iska caabinta daxalka, oo sida caadiga ah loo isticmaalo sida tuubada uumi, kala duwan ee ka kooban guud waa Al1 ~ 6%, Zn 24 ~ 42%, iyo Cu 55 ~ 71%.

-

Tube Finned Heat Beddelka

Bandhiga alaabta:

Beddelka kulaylka tubbada baalasha leh baalal leh, kaas oo ka koobnaan kara hal ama dhowr tubbo oo fin ah oo yeelan kara qolof ama qolof.Waa kulayl-bedel cusub oo ku habboon gaaska-dareeraha iyo uumiga-dareeraha kaas oo loo habeyn karo iyadoo loo eegayo shuruudaha cabbirka;tuubada fin waa qaybta aasaasiga ah ee kulaylka fin.Si loo hagaajiyo wax ku oolnimada kulaylka, fins ayaa inta badan lagu daraa dusha sare ee tuubada kulaylka, si loo kordhiyo aagga dibadda ee tuubada wareejinta kulaylka, si loo gaaro ujeedada hagaajinta waxtarka wareejinta kulaylka.

-

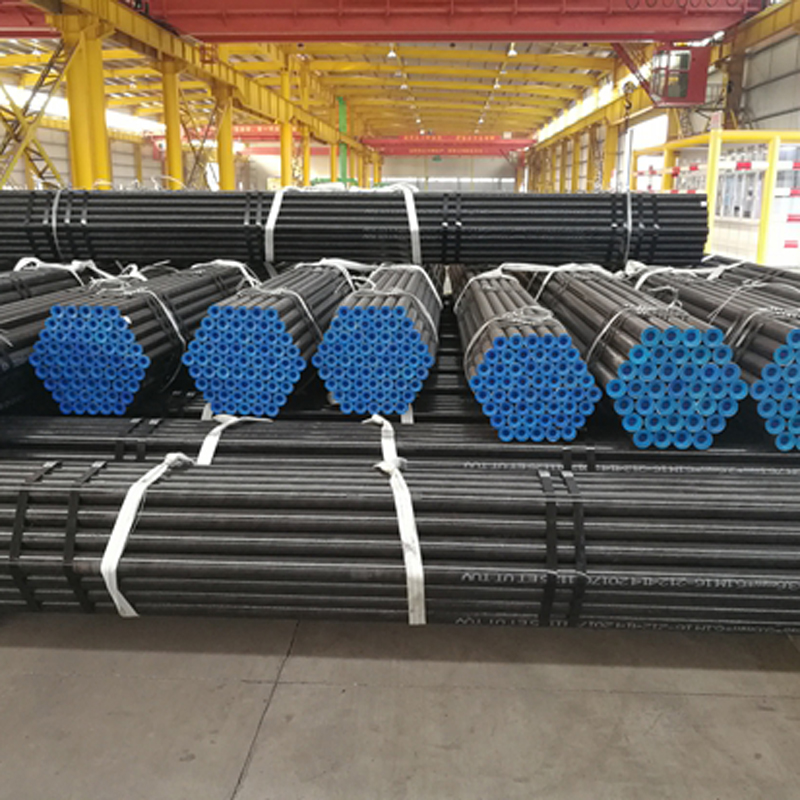

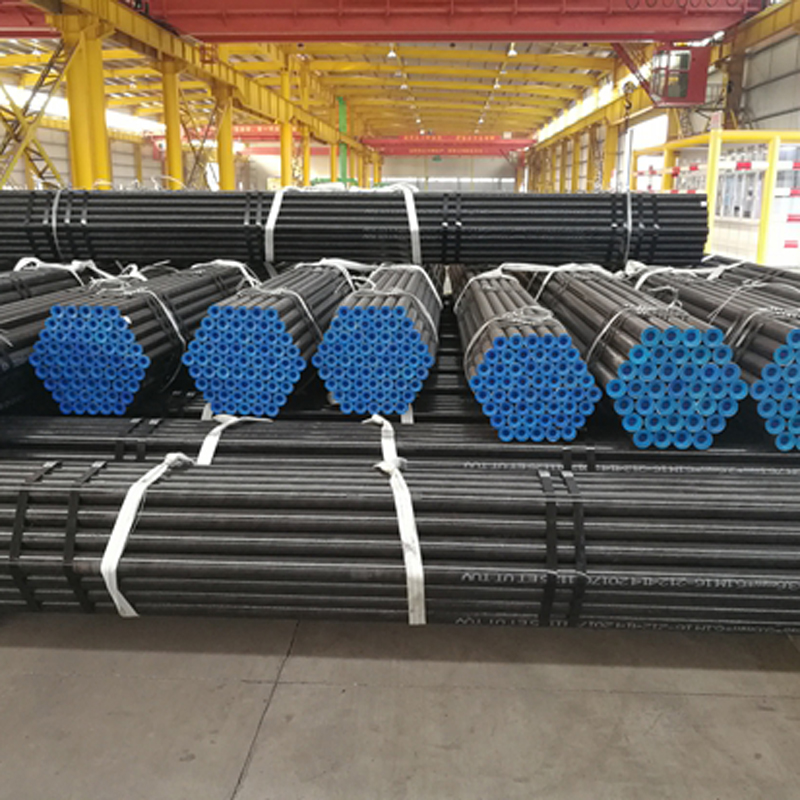

P235GH ST35.8 SA192 Kaarboon Birta Tuubbada Biyo-kaliya

Bandhiga alaabta:

Dhuumaha kululeeyaha waa nooc ka mid ah tuubooyinka aan waxba tarayn.Habka wax-soo-saarka ayaa la mid ah sida tuubada aan cillad lahayn, laakiin waxaa jira shuruudo adag oo loogu talagalay nooca birta ee loo isticmaalo soo saarista tuubada birta.Marka loo eego heerkulka isticmaalka, waxay u qaybsantaa tuubada kululeeyaha guud iyo tuubada kululeeyaha cadaadiska sare.

-

T11 T12 T22 T91 T92 Alloy Steel Dhuumaha

Bandhiga alaabta:

Tuubbooyinka birta ee Alloy-ka ah waa nooc ka mid ah birta birta ah ee aan fiicneyn, waxqabadkeedu aad ayuu uga sarreeyaa birta guud ee birta ah, sababtoo ah nooca noocaan ah ee birta ah ayaa ka kooban isbarbardhigga Cr.

Qaar badan, caabbinta heerkulka sare, iska caabinta heerkulka hooseeya, waxqabadka iska caabinta daxalka maaha mid la mid ah birta kale ee birta ah, sidaas darteed tuubada daawaha ee saliidda, warshadaha kiimikada, tamarta korontada, kuleyliyaha iyo warshadaha kale ayaa si ballaaran loo isticmaalaa.

Alloy birta birta aan seamling ka kooban yahay xubno sida Silicon, manganese, chromium, nikkel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminium, copper, boron, dhul dhif ah iyo wixii la mid ah.

-

Saxan naxaas ah, xaashi naxaas ah, gariiradda xaashida naxaasta ah

Bandhiga alaabta:

Cupronickel:

Daawaha Copper oo leh nikkel oo ah walxaha ugu muhiimsan ee lagu daray.Copper nickel binary alloy oo loo yaqaan naxaas cad oo caadi ah oo leh aluminium manganese zinc iyo walxaha kale ee daawaha naxaasta cad oo loo yaqaan naxaas cad oo adag.Naxaasta cad ee warshaduhu waxay u qaybsantaa qaab-dhismeedka naxaasta cad iyo koronto yaqaan naxaas cad laba qaybood.Naxaasta cad ee qaab dhismeedka waxaa lagu gartaa sifooyin farsamo oo wanaagsan iyo caabbinta daxalka iyo midab qurux badan.Naxaasta cad ayaa si weyn loogu isticmaalaa soo saarista muraayadaha muraayadaha saxda ah ee qalabka, mishiinka kiimikada iyo qaybaha markabka.Naxaasta cad ee korantada guud ahaan waxay leedahay sifooyin heerkulbeeg oo wanaagsan.Naxaasta cad ee Manganese oo leh maadooyin kala duwan oo manganese ah waa shay loo isticmaalo soo saarida qalabka korantada ee saxda ah

-

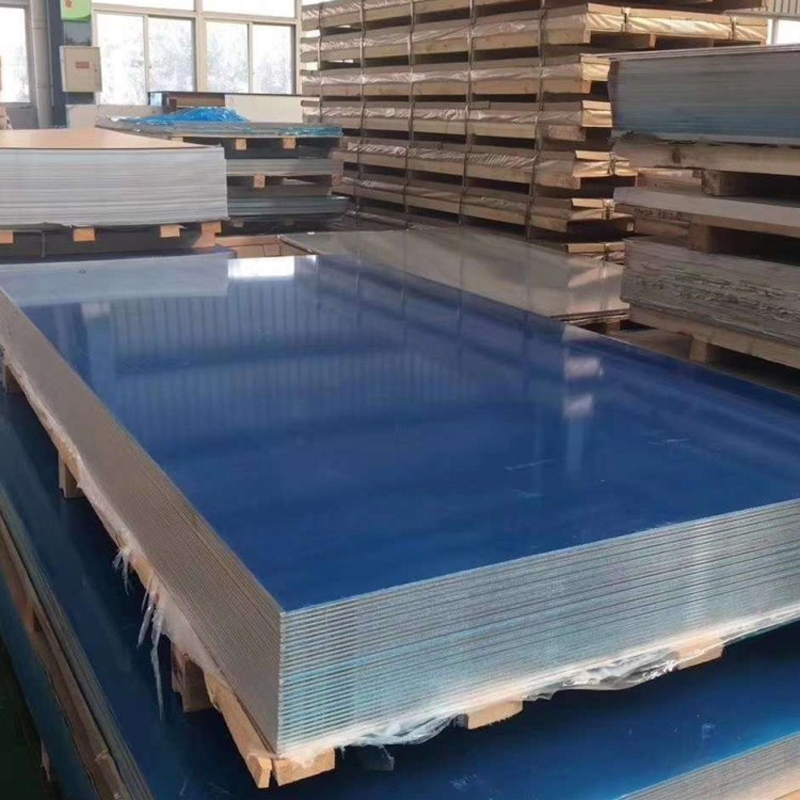

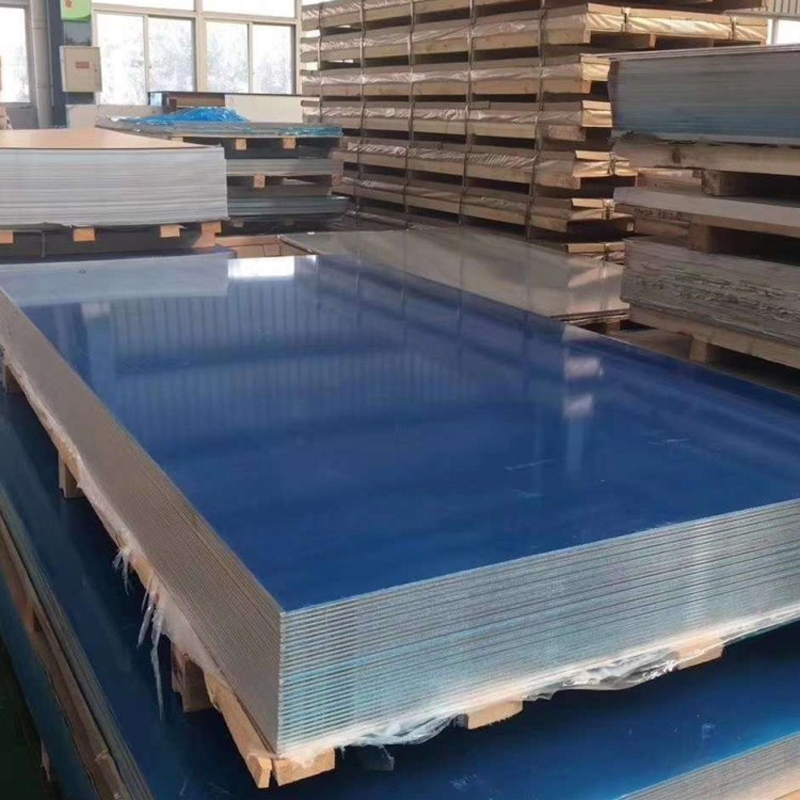

Saxan aluminium ah / Aluminium Aloy Plate / 7075/5052/6061

Bandhiga alaabta:

saxan aluminium aluminium sida waafaqsan habka daahan waxaa loo qaybin karaa: buufin alaabta guddiga iyo guddiga daahan pre-roller;

Sida laga soo xigtay nooca rinjiga waxaa loo qaybin karaa: polyester, polyurethane, polyamide, silicon modified, fluorocarbon, iwm.

Saxan aluminium-lakab ah wuxuu noqon karaa saxan aluminium saafi ah, saxan aluminium aluminium manganese ah iyo saxan aluminium alloy magnesium ah.

Looxa aluminium ee Forocarbon wuxuu leeyahay looxa buufinta fluorocarbon iyo saxan aluminium hore loo duubay oo dahaarka leh.

-

Silicon Steel Coil

Bandhiga alaabta:

Silicon alloy steel ka kooban 1.0 ~ 4.5% silicon iyo kaarboon ka yar 0.08% waxaa loo yaqaan birta silikoon.Waxay leedahay sifooyin koronto birlabeed sare leh, jujuub yar iyo is-caabbin weyn oo iska caabin ah, sidaa darteed luminta hysteresis iyo luminta hadda waa yar tahay.Inta badan waxaa loo isticmaalaa sida walxaha magnetic ee matoorada, transformers, qalabka korontada iyo qalabka korontada.Si loo daboolo baahiyaha feer iyo goynta farsamaynta marka la samaynayo qalabka korontada, caag gaar ah ayaa sidoo kale loo baahan yahay.Si loo hagaajiyo tamarta nuglaanta magnetic loona yareeyo luminta hysteresis, hoos u dhigida waxyaabaha wasakhaysan ee waxyeellada leh waa, ka sii fiican, nooca saxanka waa mid siman iyo tayada dusha sare waa mid wanaagsan.

-

304, 310S, 316, 347, 2205 Ku-xidhid Dhuumaha Aan-Aamiga ahayn

Bandhiga alaabta:

Xirmooyinka tuubooyinka aan lahayni waa erey guud oo ka mid ah qaybaha isku xidha, xakamaynta, beddelka, leexinta, xidhida iyo taageeridda nidaamka tuubada.Ku rakibida tuubooyinka waa qayb isku xidha tuubada tuubada.Qalabka tuubooyinka cadaadiska sarreeya waxay ku habboon yihiin qalabka uumiga cadaadiska sare, heerkulka sare ee kiimikada iyo dhuumaha cadaadiska sarreeya, warshadda korantada iyo maraakiibta tamarta nukliyeerka, qalabka kululeeyaha cadaadiska sare iyo jawi kale oo gaar ah.Qalabka tuubooyinka ayaa si weyn loogu isticmaalaa qaybo badan oo injineernimo sida dhismaha, warshadaha kiimikada, macdanta iyo tamarta.Doorkeeda muhiimka ah waa in aan la iska indha tirin.

-

Q355, P235GH, 210A1, T1, T11, T12 Birta Wareega ee Bar

Bandhiga alaabta:

Birta wareega ahi waa bir cylindrical adag ah, dhexroorkeeda waxaa loo qaabayn karaa qiyaaso kala duwan iyadoo loo eegayo baahida wax soo saarka.Habka habaynta waxaa ka mid ah duubitaan kulul, sawir qabow, daweyn been abuur ah iyo kulayl iyo habab kale.Waxaa ka mid ah, duubista kulul waa habka ugu badan ee la isticmaalo, kaas oo soo saari kara bir wareegsan oo leh dhexroor weyn.Habka sawirka qabow wuxuu soo saari karaa dhexroor yar iyo bir wareeg ah oo sax ah.

-

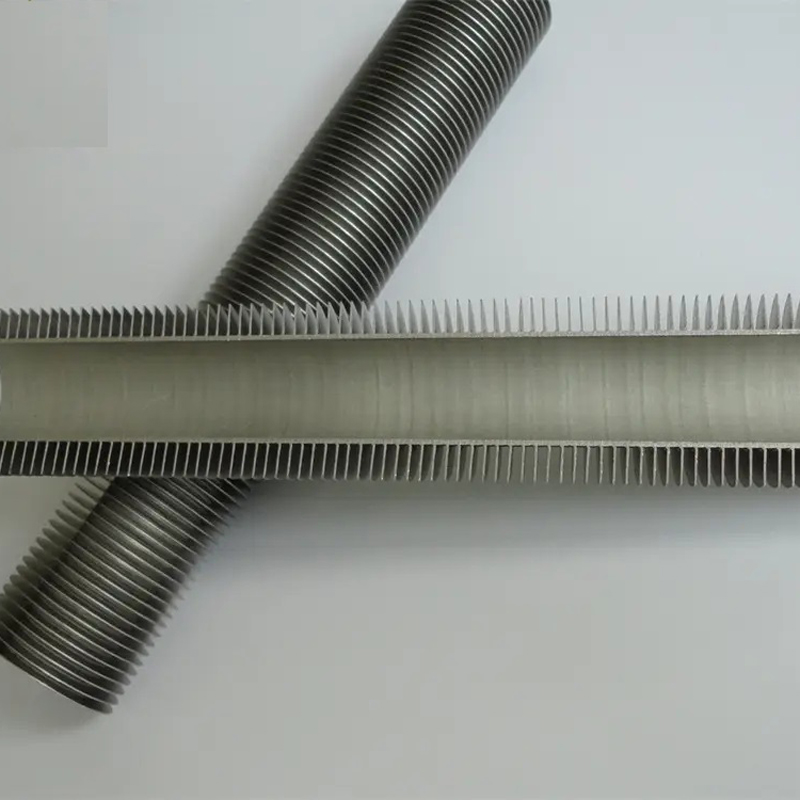

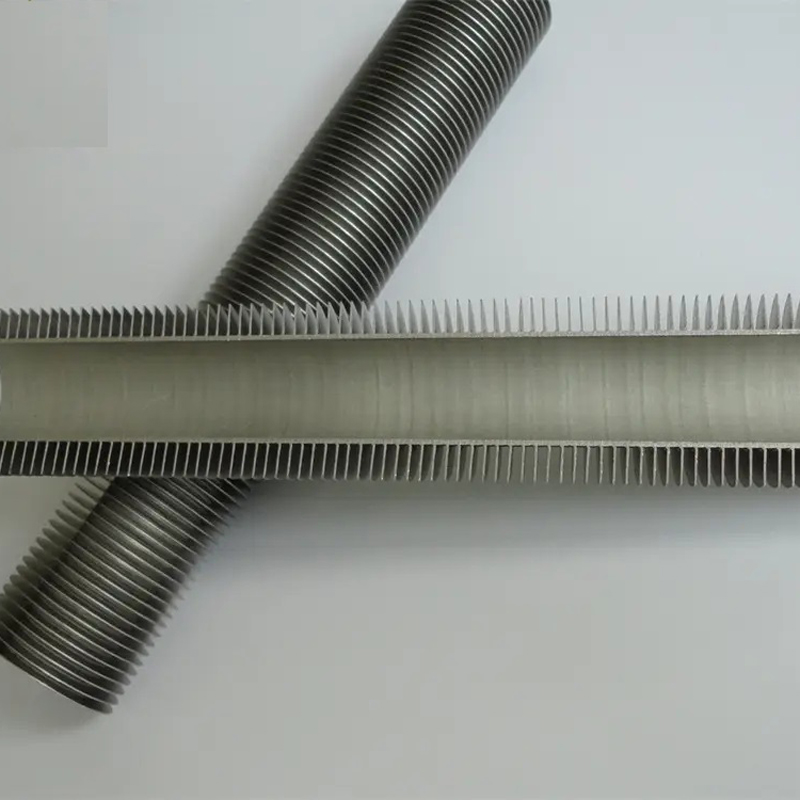

Alloy Stainless Copper Steel Fin Tube

Bandhiga alaabta:

Qaybta trapezoidal ee ay samaysay calending ee tuubada fin ee L-qaabeeya waxay ku habboon tahay xajmiga qaybinta cufnaanta qulqulka kulaylka, qaybta ayaa si dhow isku dhafan iyo waxtarka kulaylku waa sarreeyaa, taas oo meesha ka saaraysa iska caabbinta kulaylka xidhiidhka ee ay sababtay qaybta. farqiga

Heerkulka shaqada: 230 ℃

Astaamaha: isticmaalka habka dabaysha, wax-soo-saarka sare ee wax soo saarka, fogaanta isku midka ah, wareejinta kulaylka wanaagsan, saamiga garabka sare, tuubada saldhigga ayaa laga ilaalin karaa nabaad-guurka hawada.

Codsiga: inta badan loo isticmaalo petrochemical, awoodda korontada, warqad, tubaakada, kulaylinta dhismaha iyo warshadaha kale ee qaboojiyaha hawada, kuleyliyaha hawada iyo warshadaha cuntada budada borotiinka warshad, istaarijka iyo nidaamka qalajinta kale ee buufin ee kululeeyaha hawada.